Comparison between FBBR and MBBR vs MBR

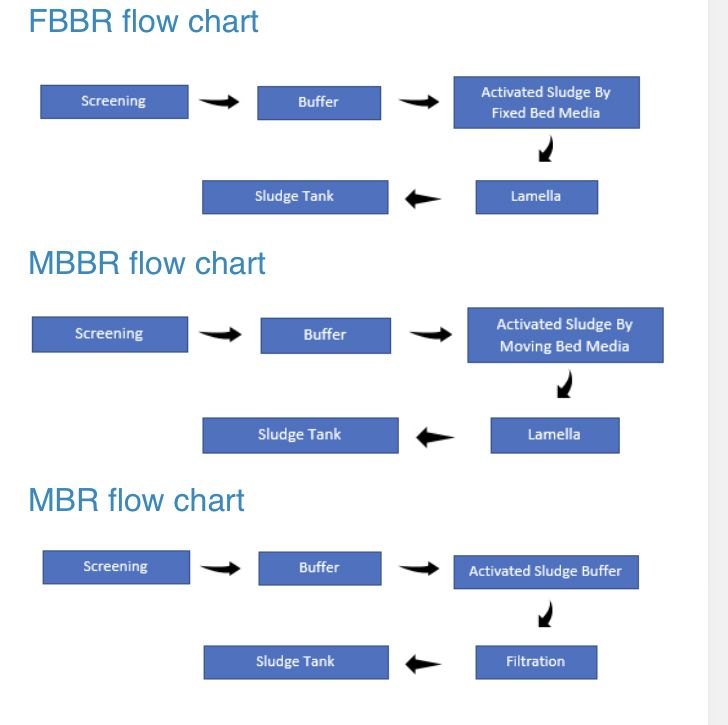

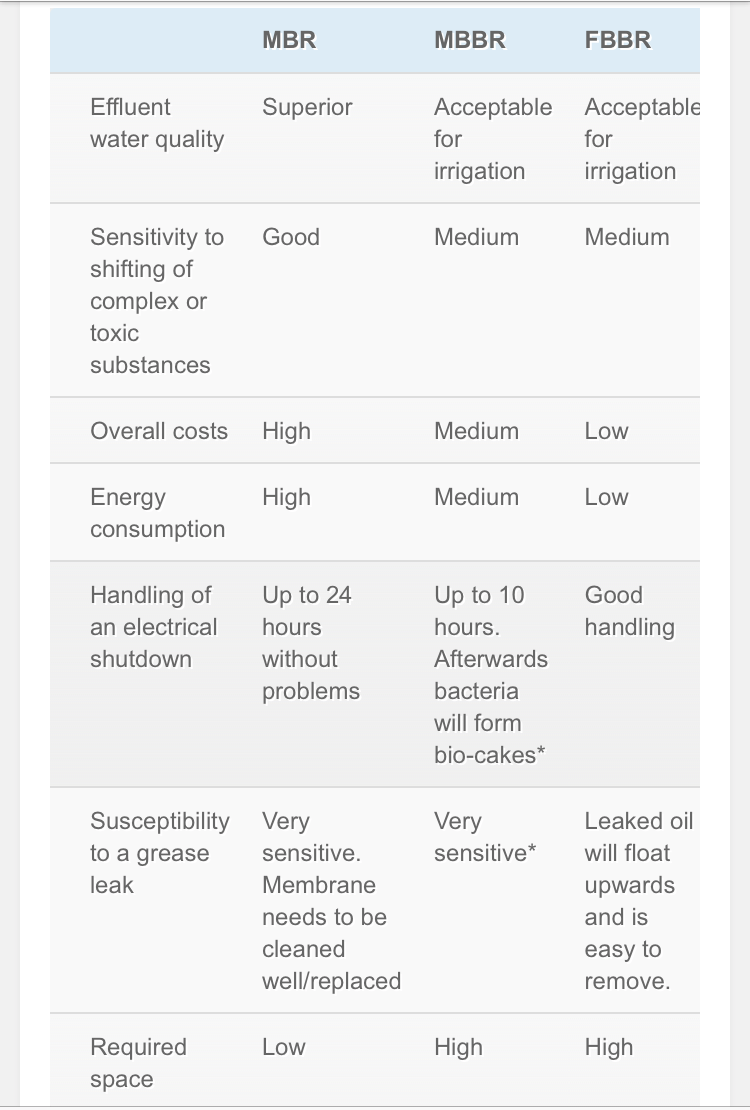

An MBR (Membrane Bio Reactor) plant uses biological breakdown and physical separation. It is a filtration facility with an upstream activated sludge buffer. The sludge production

is less than that of FBBR (Fixed Bed Bio Reactor) and MBBR (Moving Bed Bio Reactor),due to a concentration of bacteria that is 4-5 times higher (held within the membrane). On top of that, there is no sludge settlement required, so less space is needed.

FBBR flow chart

MBBR flow chart

MBR flow chart

Depending on the size of the pore diameter, even germs can be separated from the water. Negative pressure is required to support the wastewater flow through the membrane (an

energy-intensive process).

A screen forms part of the upstream equipment to prevent the membrane from clogging, (for the removal of grit and grease). It is also necessary to backwash the membrane in set intervals, too. As the membrane needs to be switched occasionally it is important to have regular professional servicing.

In contrast to MBR, FBBR and MBBR are only using bacteria for the breakdown of impurities. The upstream screening is also required, but particles smaller than 3mm are allowed to pass. Even a manual screening is acceptable. Sludge settlement is required after the bio-reactor in the form of lamella technology. Spare parts are cheaper and long lasting, so operational expenses are lower.

The FBBR plant includes a fixed bed, on which the bacteria grow. Alternatively, MBBR plants contain particles, on which the bacteria should grow. These particles are free to move within the reactor.

The developing biofilm reduces impurities and, therefore, the sludge mass (but not as effectively as an MBR plant)

* Material has to be changed, the plant will need a ten day restarting-time (green = advantage, white/grey = normal, red = disadvantage)