DIA of rubber diaphragm: 260mm

Aeration capacity: 2~5m³/h

Service Area: 0.5~0.8㎡/piece

Oxygen utilization ratio: 31-59.29%

Oxygenation capacity: 0.214-0.42 Kg O2/h

Theoretical power efficiency: 6.2-8.66kg O2/kw.h

Resistance loss: <2780Pa

Air bubble diameter: 1~3mm

Product Description

Overview of Product Development

Currently the aerator is widely used in sewage treatment process. In addition to the large consumption, it is also the core component of the sewage treatment process and can influence the operation quality and the effluent characteristics of a sewage plant directly.

In regard to the traditional aerator, its tabular rubber diaphragm is tightly attached to the plane mounting plate or the slightly raised mounting plate and is compressed fast by a screw cover. The diaphragm of such aerator is extended and stretched via the function of the elasticity of the rubber. And the stress generated when aerating is mainly at the center of and around the diaphragm. Moreover, the stretch tensor is relatively small. As a result, the aeration resistance is high and the diaphragm is liable to aging, which weakens the oxygenation capacity, increases the power consumption and augments the workload of maintaining and replacing the equipment.

To remedy the mentioned shortcomings of the traditional aerator, our company, working together with famous domestic colleges, has developed a new generation aerator, namely, Disk-type rubber diaphragm microporous aerator.

Product Feature

※ The tabular rubber diaphragm of the traditional aerator is changed for rubber diaphragms with compensation for extension, which can remarkably increase the service life of the aerator.

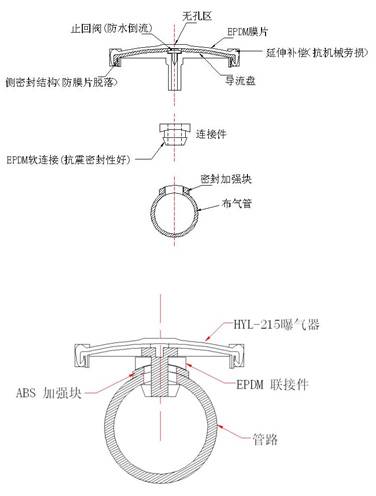

※ The left-hand folding structure of better sealing property is used between the diaphragm and the mounting plate, which can effectively prevent the diaphragm from coming off.

※ An internal check valve structure is designed for the diaphragm. With no hole provided, the center of the diaphragm is thickened. When the valve is closed to stop the air supply, the center part of the diaphragm can fall back onto the hole of the supporting plate due to the water pressure and the diaphragm’s elasticity. Meanwhile, the area with no hole can cover exactly the air release hole. That’s just like a check valve capable of preventing liquid from flowing back into the aeration system.

※ An independent T-shape check valve is provided inside the aerator, which can make sure no water will flow into the pipelines even if the diaphragm is broken. Hence, such kind of aerator is perfectly suitable for intermittent aeration system, such as SBR process.

※ The diaphragm is made from imported ethylene-propylene diene copolymer (EPDM), which makes the diaphragm anti-aging, corrosion-resisting and durable.

※ Bubbles generated during the aerating process are fine, that is, their diameter is small, which can weaken the shear failure of sludge particles.

※ An unique flexible connection type is used to connect the aerator and the pipeline, which can effectively improve the sealing property and prevent connecting pieces from breaking because of the vibration generated when the aerator is in operation.

※ Such kind of aerator can stand a temperature of 150℃ at utmost and can be used for aeration in a pool where the water is as deep as 10 m.

Main Uses and Application Scope

This microporous aerator can be applied to the aeration oxygenation process in the treatment of different types of sewage.

Its performance indexes are totally up to the provisions of CJ/T3015.1-1993 and CJ/T 264-2007

Condition of using environment | Can work in the environment air temperature 90-100℃ |

| Ambient temperature of external climate | -30-45℃ |

| Medium temperature | 4-50℃ |

| PH value | 4-9 |

| Maximum immersion depth | 10.0m |

| Work system | 24h/day Continuous or intermittent work |

Structural Features

Disk-type diaphragm microporous aerator is mainly made of diaphragm, check valve, fixing ring and aerator tray.

The diaphragm of the aerator is made from imported EPDM, so it is efficient in resisting the ozone oxidation. Such kind of rubber can stand a high temperature up to 150℃ or a low temperature down to -50℃. In addition, it can resist organic solvent and inorganic substances effectively. And its compression resistance and elongation can be respectively up to 25 MPa and 500%.

The diaphragm of the aerator consists of 2,700-6,600 micro pores. Since a special one-step molding technology is employed, the pores are uniform and the distribution of airflow on the whole diaphragm is quite even, which guarantees the stability and all-sidedness of the contact of airflow and sewage. When the aerator is in operation, the diameter of the bubbles is even, ranging between 1 mm and 3 mm.

As for disk-type diaphragm microporous aerator, there is a downward-opening ring-type groove at the outer edge of the back of the mounting plate. The side of the diaphragm extends downward to buckle the groove at the back of the mounting plate to form a seal structure, which enhances the sealing property of the product and can effectively prevent the diaphragm from coming off. Moreover, there is an upward thickened convex edge at the top of the diaphragm, which can compensate the extension and increase the service life.

There are two ways to fix the disk-type diaphragm microporous aerator to the air pipeline system, namely, screw-type hard connection and stress expansion flexible connection. Typically, the latter way is adopted.

Just like the diaphragm, flexible connecting pieces are made of EPDM as well. So they are of good shock resistance and sealing property. Hence, they can protect the junction from breaking due to vibration caused by air blast, and meanwhile make the junction more reliable and better sealed. Moreover, retaining blocks are provided for the pipelines to enhance the reliability of the flexible connection. At the same time, the flexible connecting pieces are not fixed onto the pipelines with glue, which makes the replacement or maintenance more convenient.

Leave a message for me

Thank you for visiting official website!

If you have any question, please leave your valuable comments and suggestions.

We will arrange the relevant personnel to know the actual situation and contact you when we receive them.